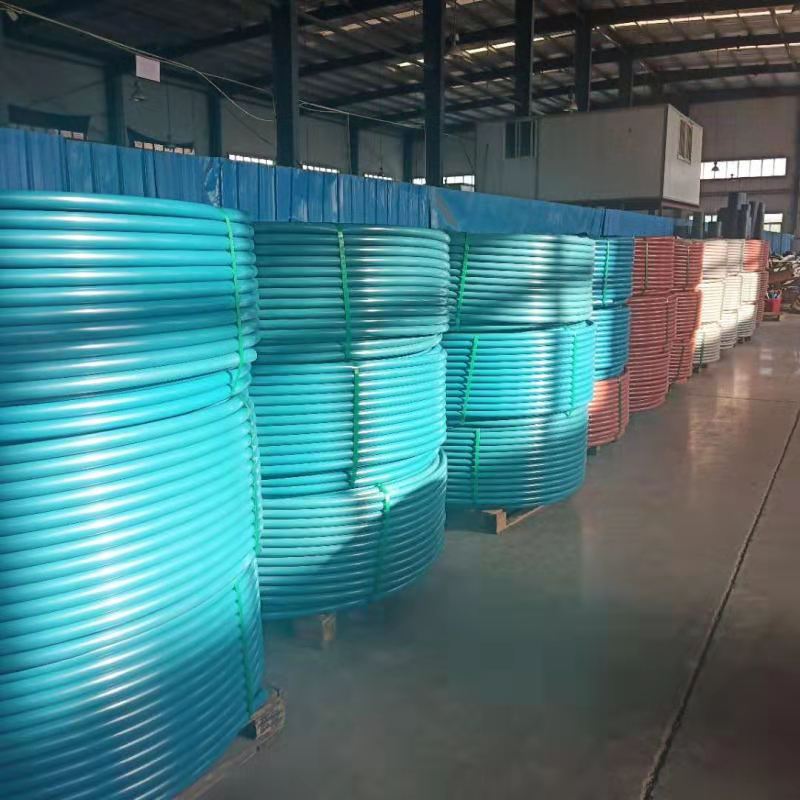

PE threading pipe

Characteristics of PE threading pipe:

(1) Reliable connection: the polyethylene pipe system is connected by electrothermal fusion, and the strength of the joint is higher than that of the pipe body.

(2) Good low temperature impact resistance: the low temperature embrittlement temperature of polyethylene is very low, and it can be safely used in the temperature range of - 60-60 ℃. In winter construction, because of the good impact resistance of the material, there will be no brittle crack of the pipe.

(3) Good stress cracking resistance: PE pipe has low notch sensitivity, high shear strength, excellent scratch resistance and excellent environmental stress cracking resistance.

(4) Good chemical corrosion resistance: PE pipeline can resist the corrosion of a variety of chemical media, and the chemical substances in the soil will not degrade the pipeline. Polyethylene is the insulator of electricity, so it will not rot, rust or electrochemical corrosion; In addition, it does not promote the growth of algae, bacteria or fungi.

(5) Aging resistance and long service life: polyethylene pipes containing 2% - 2.5% carbon black with uniform distribution can be stored outdoors or used for 50 years, and will not be damaged by ultraviolet radiation.

(6) Good wear resistance: the comparative test of wear resistance between PE pipe and steel pipe shows that the wear resistance of PE pipe is 4 times of that of steel pipe. In the field of slurry transportation, compared with steel pipe, PE pipe has better wear resistance, which means that PE pipe has longer service life and better economy.

(7) Good flexibility: the flexibility of PE pipe makes it easy to bend. In engineering, it can bypass obstacles by changing the direction of the pipe. In many cases, the flexibility of the pipe can reduce the amount of pipe fittings and reduce the installation cost.

(8) Low flow resistance: PE pipe has smooth inner surface, and its Manning coefficient is 0.009. The smooth performance and non adhesion characteristics ensure that PE pipe has higher conveying capacity than traditional pipe, and also reduce the pressure loss and energy consumption.

(9) Convenient handling: PE pipe is lighter than concrete pipe, galvanized pipe and steel pipe, it is easy to handle and install, lower manpower and equipment requirements, which means that the installation cost of the project is greatly reduced.

(10) A variety of new construction methods: PE pipeline has a variety of construction technologies, in addition to the traditional excavation method, it can also use a variety of new trenchless technologies, such as pipe jacking, directional drilling, lining, pipe cracking and so on, which is the only choice for some places that are not allowed to excavate, so PE pipeline is more widely used